K 2025 trade fair for plastics & rubber: Wacker - New silicone rubber increases safety of traction batteries in electric cars

At the K 2025 International Trade Fair for Plastics and Rubber, WACKER is all set to unveil a new silicone rubber that reliably insulates busbars in high-voltage batteries of electric cars. As it can be processed by extrusion, the new product called ELASTOSIL® R 531/60 makes the sheathing of such components very cost-effective. What is more, in the event of fire the product ceramifies and forms an electrically insulating protective layer that reliably prevents short circuits. ELASTOSIL® R 531/60 thus plays a vital role in passenger and fire safety of electric vehicles. K 2025 will be held in Düsseldorf, Germany, from October 8 to 15.

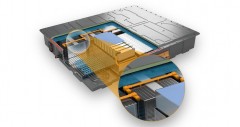

400 volts, 800 volts, 915 volts: the voltage range in electric cars seems to be heading in only one direction – upwards. However, the quest for more power, shorter charging times and longer ranges comes at a price: namely, significantly greater demands in terms of wiring and insulating electrical components. This applies in particular to busbars of traction batteries, which basically are aluminum

or copper rails that distribute the current between the battery cells and modules.

As nominal battery voltages in electric vehicles are already in the range of 300 V to 900 V, the reliable insulation of these components is a must.

WACKER’s new silicone rubber ELASTOSIL® R 531/60 meets these demands perfectly. The product is flame-resistant and reliably prevents leakage currents and energy losses. The insulation remains intact, even at operating temperatures of up to 205 °C. ELASTOSIL® R 531/60 has yet another important role in the safe operation of electric vehicles. In the event of a fire, the cured rubber forms a solid ceramic material that sheaths the busbar and continues to insulate it electrically, thus reliably preventing short circuits. This protective layer remains intact even at temperatures between 800 and 1000 °C.

With a hardness of 60 Shore A, ELASTOSIL® R 531/60 makes processing costeffective as it can be applied to a busbar by extrusion. The high flexibility and tear strength of the silicone allow busbars to be bent and adapted to the surface structures of the battery without cracking. No fractures or cracks occur even after impact tests. ELASTOSIL® R 531/60 can easily withstand temperature fluctuations and is extremely flexible, even at temperatures down to 40 °C, protecting the battery from vehicle body vibrations and impacts.

Visit WACKER at K 2025 from October 8 to 15, in Hall 6, Booth A10