Esko demonstrates at Labelexpo Americas 2018 a wide range of solutions and product integrations that result in ‘Packaging Connected’

Esko tools offer faster, error-free label production, with exceptional quality through unique, functional integrated tools.

The challenges facing label converters today center around producing high volumes of short run jobs with quicker deadlines and better quality. This situation can easily be handled with optimized workflows that link all supply chain partners.

At Labelexpo Americas 2018, visitors to the Esko (www.esko.com) booth (#5202) will learn how integrated and automated solutions, such as color specification, 3D pack shots and design reviews, can link brand owners, designers, premedia and the pressroom into a highly productive and efficient workflow. The result – Packaging Connected – drives faster throughput, higher quality, and ‘Right First Time’ production.

From Design to Print

Visitors are welcome on the Esko booth, to see a demonstration of each leading component of Esko’s Packaging Connected solution, including:

- Job specification data: Esko WebCenter is the leading solution for job specification data flows all the way from MIS/ERP systems to the press control station, automating press setup and inline quality inspection setup, driving faster setup time, less waste, and greater equipment uptime.

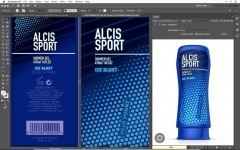

- Design: Esko Studio and Store Visualizer are the preferred solutions for designers, helping them to create better artwork and hyper-realistic 3D mockups for presentation, proofing and quality control. The automated creation of virtual 3D nine-view pack shots added to a digital job asset library drives a consistent consumer experience across all media channels, online and physical packs—and ultimately connects the consumer with the brand through the package.

- Color specification: X-Rite ColorCert Suite is the prime solution to simplify color communication across all internal and external stakeholders, from design to the AVT inline inspection system, removing errors and enabling faster setup time, and longer equipment uptime. This is significant for label producers with many short run jobs.

- Digital job assets are stored centrally in MediaBeacon, the leading marketing asset management solution and shared with all stakeholders, from the brand’s product and online marketing teams to the designers and prepress department. The new MediaBeacon connectors for the Adobe Creative Suite applications significantly simplify sharing of brand marketing assets. This guarantees consistency between online and physical brand assets, and assures a consistent brand experience for the consumer.

- Centrally stored and approved packaging content: With pre-approved marketing assets—such as ingredient copy, marketing slogans, logos and symbols—centrally stored in Esko WebCenter, creation of packaging variants can be a 100% automated process, resulting in error reduction, faster time to market, and quicker response to changes.

“The label industry needs answers to ever tighter deadlines and shorter print runs,” explains Udo Panenka, Esko President. “At our recent EskoWorld users conference, we proudly demonstrated to more than 500 Esko users how Esko connected software and hardware solutions help the entire packaging ecosystem to collaborate more efficiently and solve their key challenges. Esko supports label printers to reduce time-to-market from currently 198 days to an aspiring 30 days, to produce better quality labels and to reduce errors. Not only do we connect the supply chain – we make it easier for brand owners to connect to their consumers with less expensive, more impactful packaging.”